The Buzz on Steel Fabrication And Welding

Wiki Article

All About Steel Fabrication

Table of ContentsSteel Fabrication for BeginnersExamine This Report about Fabricated Steel AngleAll About Steel Fabrication IndustryEverything about Steel Fabrication Near MeHow Steel Fabrication Business can Save You Time, Stress, and Money.

Machining, Machining is additionally a relatively basic process in principle, and also yet there is a variant that can be found in it. By its nature, it is a process of getting rid of excess product from raw metal pieces somehow. Three of the extra well-known procedures of machining are called milling, transforming, and drilling.This procedure can be done both with the help of a details CNC milling device and by hand, as well as milling, in basic, is much more usually a second process than not. Some variants of milling can be plain milling, climb milling, type milling, angular milling, and so forth. Turning is an additional variant of machining that utilizes an especially created device lathe to develop a cylindrical-shaped item by using a reducing device to remove parts of a raw steel piece that turns in one area.

Exploration is the most basic one out of the 3, and it's equally as the name suggests it's the mix of a drill and a rotary reducing device made use of to reduce holes in the raw steel piece. steel fabrication business. Shearing, Shearing is practically a variant of reducing, however it's divided right into a various group as a result of its uncommon strategy to the process.

Some Known Factual Statements About Steel Fabrication Process

The cut is started by using stress to the metal item with the upper part of a maker (formed like a blade), which develops a crack. By applying continuously stress to the fractured metal a cut is accomplished, and the sheared sides can be burred afterward (burred as if the procedure of tidying up the edges of the material pieces after the shearing).It is quite a widely known approach, mainly due to its flexibility it can incorporate practically any type of steel components. There are four types of welding that are the most prominent: FCAW, MIG/GMAW, SMAW, and also TIG.FCAW or Flux Cored Arc Welding uses a cable electrode with a core that generates securing gas, which eliminates the demand for a secondary gas resource.

It uses an exterior gas supply in combination with a solid wire electrode to prevent the metal piece from connecting with different ecological factors, making the procedure much faster as well as extra consistent. SMAW or Shielded Metal Arc Welding is one of the most fundamental variation of a welding device, it's an electrode stick that forms an electrical arc when exposuring to steel, and also the high temperature of the arc's effect is what welds the steel assemble.

An Unbiased View of Fabrication Steel Chart

It utilizes a tungsten electrode rod that produces brief arcs, more appropriate for heavy fabrication - fabricated steel angle. It is among the more tough variants of welding as well as calls for a highly-skilled specialist to operate it properly, yet it also benefits the majority of metal-based products and also comes in useful even for the most complex tasks.This post is an attempt to incorporate some of the more fundamental details on the subject in one location, from the interpretation of steel construction to a myriad of processes that it can take the type of.

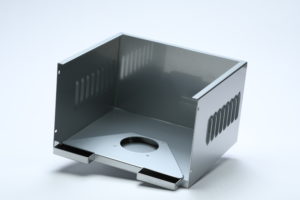

Sheet metal check can be specified as any kind of steel that is developed right into thin flexible sheets. The sheets range in material from brass to titanium and also come in a variety of predefined densities, referred to as a gauge. Commonly, many sheets are less than inch thick but can range in density from portions of a millimeter to numerous inches thick.

The smart Trick of Steel Fabrication Apprenticeship That Nobody is Discussing

Historically, it was utilized in tile roof, but as production strategies improved, sheet steel soon supplied a cheap and long lasting product that might be utilized practically everywhere. It ended up being so prominent that suppliers saw a boom until Globe War II when steel materials became so scarce that the sector began to collapse.

In addition, it is much faster to scale mass manufacturing because of the flexibility of construction choices. Given that it is thin and has a light-weight type aspect, any type of steel fabrication business plan pdf extra supply needed for manufacturing can be kept and also moved conveniently. There are dozens of means to produce sheet metal depending upon the application.

Flexing, Sheet steel is placed within a bending maker and bent to the wanted form. Stamping, A sheet steel space is positioned into a marking press where it is created into the wanted form utilizing a device and also die.

wikipedia reference

Unknown Facts About Steel Fabrication Apprenticeship

This process employs using a high-powered laser to cut products to the wanted sizes and shape. Contrasted to other cutting procedures, it offers greater cutting precision as well as precision, particularly for facility and also complex component designs. Machining Machining is a subtractive procedure, meaning it develops parts as well as products by getting rid of material from the workpiece.

Report this wiki page